MS Pipe End Caps

MS Pipe End Caps Specification

- Shape

- Round

- Packaging Type

- Carton/Bag/Loose

- Cap Type

- Dome End Cap

- Product Type

- MS Pipe End Cap

- Material

- Mild Steel

- Type

- Weldable

- Treatment

- Hot Rolled

- Usage

- Pipe fitting/closure protection

- Diameter

- Available from 1/2 inch to 36 inch

- Width

- Customizable depending on pipe size

- Size

- Standard and custom sizes

- Color

- Metallic Grey/Black

About MS Pipe End Caps

MS Pipe End Caps

We offer MS Pipe End Caps, which are manufactured using above mention grade raw material and cutting edge production techniques. Ideal for the MS pipes, these protection caps are offered in standard and customize designs to meet the specific requirements of the individual customers in diverse industries. Moreover, our large production capacity also enables us in meeting both the small and voluminous demands of the clients within given time frame

Versatile Customization and Sizing

Our MS Pipe End Caps can be crafted in both standard and custom sizes to fit project specifications. Ranging in diameter from 1/2 inch up to 36 inch, we offer tailored solutions for complex pipeline systems. The width and thickness can also be customized, ensuring an optimal fit and performance for every unique installation.

Reliable Protection and Durability

Constructed from robust mild steel and finished with advanced hot-rolled techniques, these end caps exhibit dependable rust and chemical resistance. The smooth or matte surface not only enhances aesthetics but also improves longevity in challenging environments, making them a preferred choice for oil, gas, water, and industrial sectors.

FAQs of MS Pipe End Caps:

Q: How are MS Pipe End Caps typically installed?

A: MS Pipe End Caps are usually installed via butt welding at the end of pipes, creating a secure and leak-proof seal. This ensures the pipeline remains protected from external contaminants and mechanical damage.Q: What benefits do smooth or matte surface finishes offer for these pipe end caps?

A: A smooth or matte surface finish enhances corrosion resistance and provides a clean appearance, reducing the buildup of debris or residue and maintaining structural integrity over time.Q: What is the standard material and treatment used for these end caps?

A: They are manufactured from mild steel and undergo hot-rolled treatment, which increases the end caps durability, hardness, and resistance to wear and tear, making them suitable for demanding industrial use.Q: Can the MS Pipe End Caps be customized for specific project requirements?

A: Yes, our end caps are available in both standard and custom configurations. They can be crafted according to detailed drawings or specific client requirements for diameter, width, thickness, and other parameters.Q: Where are these pipe end caps most commonly used?

A: These end caps are widely utilized in the oil and gas industry, water supply networks, construction projects, and various industrial piping systems to provide secure closure and protection.Q: What is the minimum order quantity, and can small or large volume orders be accommodated?

A: The minimum order quantity is flexible and determined by the clients needs, making it convenient for both small-scale prompt requirements and larger, bulk orders.Q: What are the packaging options available for MS Pipe End Caps?

A: They can be packed in cartons, bags, or supplied loose, depending on the quantity and specific transportation requirements, ensuring safe delivery to any location within or outside India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in M.S Pipe End Cap Category

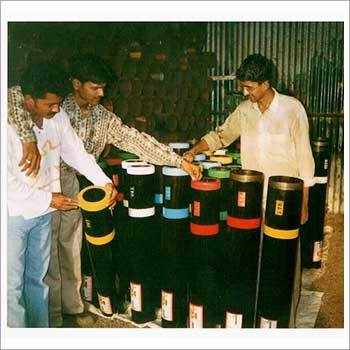

M.S. Pipe Thread Protection End Caps

Shape : Round

Diameter : 1/2 inch to 24 inch (custom sizes available)

Color : Black, Red, Yellow, Blue (as per requirement)

Usage : Other, Protects pipe thread ends during storage and transport

Product Type : Thread Protection End Cap

Cap Type : End Cap

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS